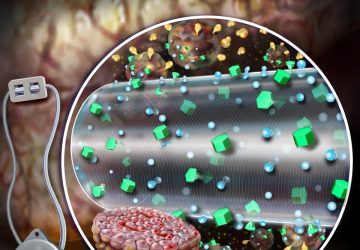

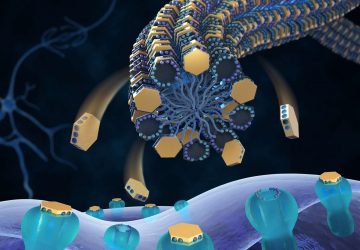

Microscopic versions of the cocoons spun by silkworms have been manufactured by a team of researchers. The tiny capsules, which are invisible to the naked eye, can protect sensitive molecular materials, and could prove a significant technology in areas including food science, biotechnology and medicine.

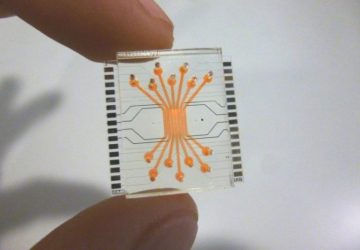

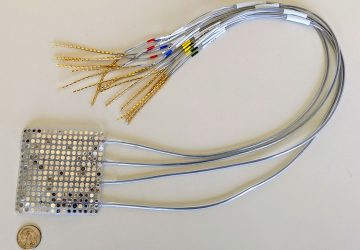

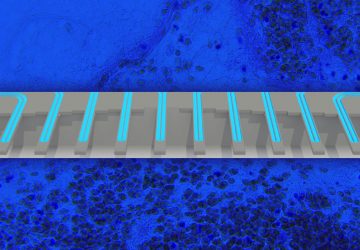

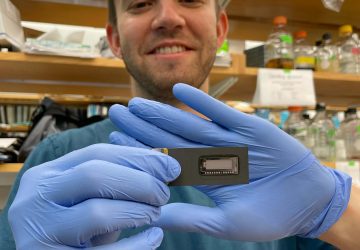

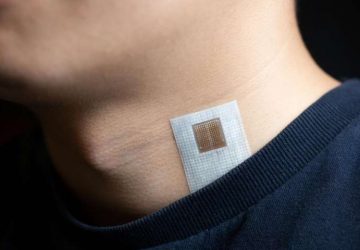

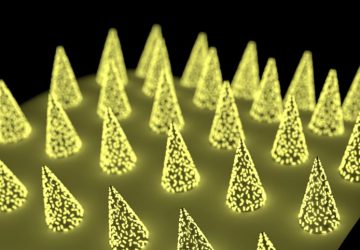

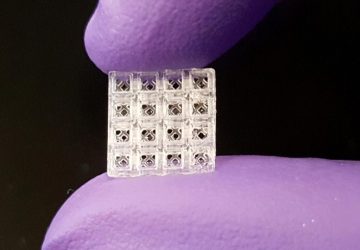

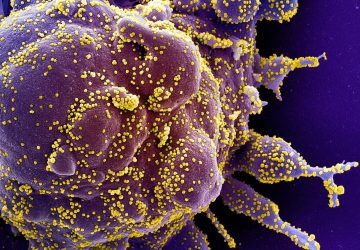

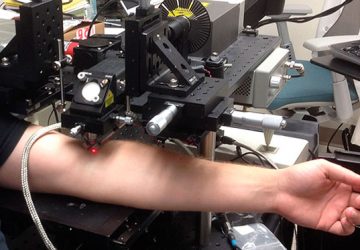

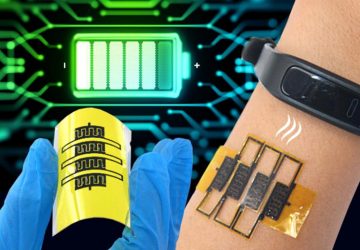

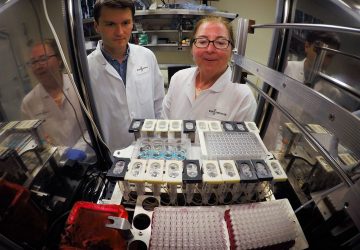

The capsules were made at the University of Cambridge using a specially-developed microengineering process. The process mimics on the microscale the way in which Bombyx mori silkworms spin the cocoons from which natural silk is harvested. The resulting micron-scale capsules comprise a solid and tough shell of silk nano-fibrils that surround and protect a centre of liquid cargo, and are more than a thousand times smaller than those created by silkworms.Writing in the journal Nature Communications, the team suggest that these “micrococoons” are a potential solution to a common technological problem: How to protect sensitive molecules that have potential health or nutritional benefits, but can easily degrade and lose these favourable qualities during storage or processing.The study argues that sealing such molecules in a protective layer of silk could be the answer, and that silk micrococoons that are far too small to see (or taste) could be used to house tiny particles of beneficial molecular “cargo” in various products, such as cosmetics and food.The same technology could also be used in pharmaceuticals to treat a wide range of severe and debilitating illnesses. In the study, the researchers successfully showed that silk micrococoons can increase the stability and lifetime of an antibody that acts on a protein implicated in neurodegenerative diseases.The work was carried out by an international team of academics from the Universities of Cambridge, Oxford and Sheffield in the UK; the Swiss Federal Institute of Technology in Zurich, Switzerland; and the Weizmann Institute of Science in Israel. The study was led by Professor Tuomas Knowles, a Fellow of St John’s College at the University of Cambridge and co-director of the Centre for Protein Misfolding Diseases.”It is a common problem in a range of areas of great practical importance to have active molecules that possess beneficial properties but are challenging to stabilise for storage” Knowles said. “A conceptually simple, but powerful, solution is to put these inside tiny capsules. Such capsules are typically made from synthetic polymers, which can have a number of drawbacks, and we have recently been exploring the use of fully natural materials for this purpose. There is potential to replace plastics with sustainable biological materials, such as silk, for this purpose.”Dr. Ulyana Shimanovich, who performed a major part of the experimental work as a St John’s College Post-Doctoral research associate, said: “Silk is a fantastic example of a natural structural material. But we had to overcome the challenge of controlling the silk to the extent that we could mould it to our designs, which are much smaller than the natural silk cocoons.”Dr. Chris Holland, co-worker and head of the Natural Materials Group in Sheffield added: “Silk is amazing because whilst it is stored as a liquid, spinning transforms it into a solid. This is achieved by stretching the silk proteins as they flow down a microscopic tube inside the silkworm.”To imitate this, the researchers created a tiny, artificial spinning duct, which copies the natural spinning process to cause the unspun silk to form into a solid. They then worked out how to control the geometry of this self-assembly in order to create microscopic shells.Making conventional synthetic capsules can be challenging to achieve in an environmentally friendly manner and from biodegradable and biocompatible materials. Silk is not only easier to produce; it is also biodegradable and requires less energy to manufacture.”Natural silk is already being used in products like surgical materials, so we know that it is safe for human use,” Professor Fritz Vollrath head of the Oxford Silk Group said. “Importantly, the approach does not change the material, just its shape.”Silk micrococoons could also expand the range and shelf-life of proteins and molecules available for pharmaceutical use. Because the technology can preserve antibodies, which would otherwise degrade, in cocoons with walls that can be designed to dissolve over time, it could enable the development of new treatments against cancer, or neurodegenerative conditions such as Alzheimer’s and Parkinson’s Diseases.To explore the viability of silk microcapsules in this regard, the researchers successfully tested the micrococoons with an antibody that has been developed to act on alpha-synuclein, the protein that is thought to malfunction at the start of the molecular process leading to Parkinson’s Disease. This study was carried out with the support of the Cambridge Centre for Misfolding Diseases, whose research programme is focused on the search for ways of preventing and treating neurodegenerative conditions such as Alzheimer’s and Parkinson’s diseases.”Some of the most efficacious and largest selling therapeutics are antibodies,” Michele Vendruscolo, co-director of the Cambridge Centre of Misfolding diseases, said. “However, antibodies tend to be prone to aggregation at the high concentrations needed for delivery, which means that they are often written off for use in treatments, or have to be engineered to promote stability.””By containing such antibodies in micrococoons, as we did here, we could significantly extend not just their longevity, but also the range of antibodies at our disposal,” Knowles said. “We are very excited by the possibilities of using the power of microfluidics to generate entirely new types of artificial materials from fully natural proteins.”

Source : www.sciencedaily.com