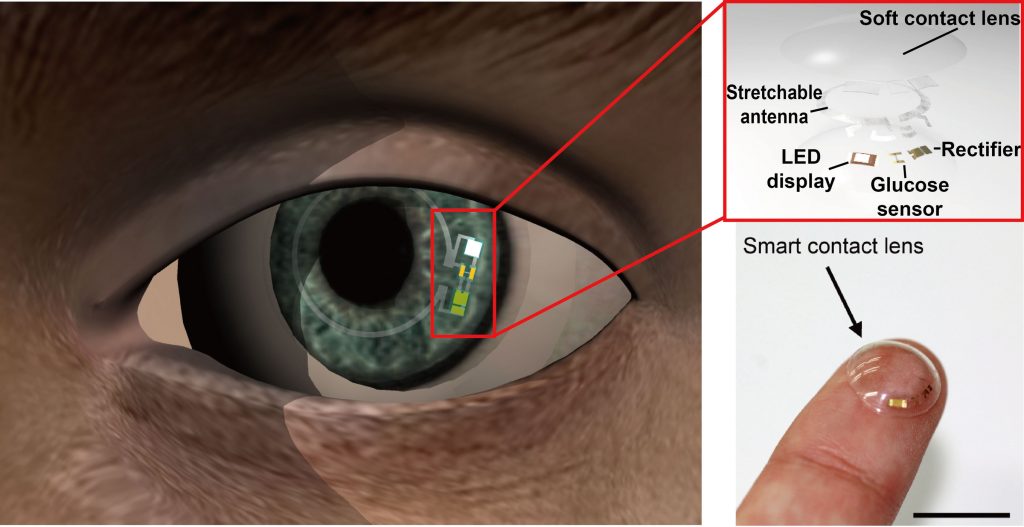

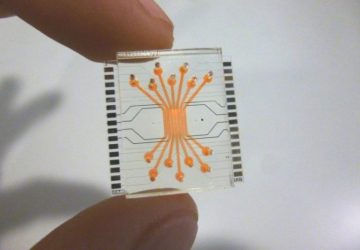

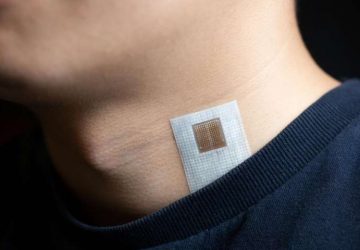

Smart contact lenses with embedded electronics just got a lot more practical. Korean researchers have designed a stretchable contact lens that can monitor glucose without distorting the wearer’s vision, according to a report published today in Science Advances.

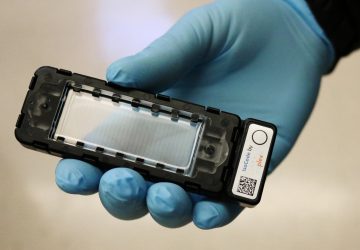

The device contains all the electronic components needed to wirelessly receive power, monitor glucose levels, and generate an LED display, while maintaining the soft, stretchable, and transparent qualities of a contact lens that people might actually be willing to wear.

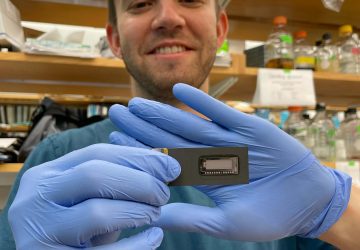

“This gets close to a solution that you can imagine a patient using,” says Gregory Herman, a chemical engineer at Oregon State University who is developing transparent sensors for contact lenses and was not involved in today’s report.

Many people with type 1 diabetes must monitor their glucose throughout the day with finger-stick blood tests. A contact lens equipped with tear-collecting sensors would provide a noninvasive alternative—a way to passively track a health condition without having to constantly think about it.

Previous smart contact lens designs for glucose monitoring, such as the one patented by Verily, Alphabet’s life-science arm, have fallen short. They tend to have electronic components fabricated on hard substrates that are inserted into a contact lens, says Jang-Ung Park, an associate professor at the school of materials science and engineering at Ulsan National Institute of Science and Technology (UNIST) in South Korea, who coauthored the report. The result is a contact lens that is brittle and can break down over time, and can also impede the user’s field of vision, Park says.

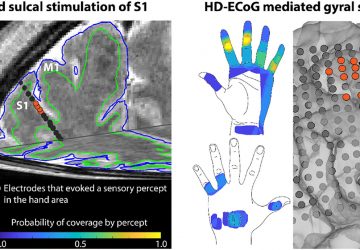

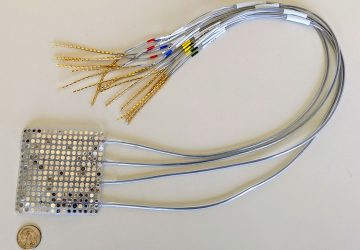

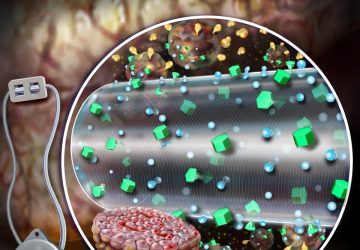

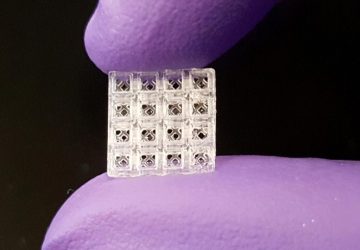

In UNIST’s prototype, segments of rigid electronic components, including circuits, antennas, LEDs, and sensors, are isolated into “islands” interconnected by stretchable conductors. Between the islands is a soft, elastic material. The pattern, which looks a bit like the spots on a giraffe, distributes mechanical strain. That protects the electronics from being deformed when the contact lens is handled by the user.

The group also managed to match the refractive indices of the islands and the elastic material, minimizing the scatter of light and improving transparency. “It’s a robust design,” says Herman. “I’m impressed by this group and how far they’re advancing the technology.”

When the user’s glucose levels are normal, the LED light stays on, and when levels move out of the normal range, the light turns off. Park says he plans to link the device to a software app that will also indicate glucose levels.

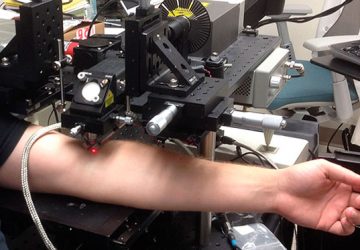

Park’s group tested the lens on a rabbit for 5 hours, and found that it did not cause irritation. The group also aimed a camera through the lens and took pictures, reporting that the clarity was good.

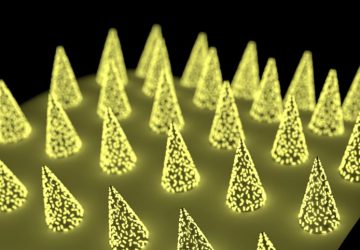

A drawback of the design is that it requires an external power source to be held at a maximum distance of 9 millimeters from the contact lens. “There’s a trade-off you make when you go for transparency,” says Herman. The antenna is made of long metal nanofibers that, while stretchable and invisible to the user, have lower conductivity and need to operate at lower frequencies. This means that the power-source coil must be closer to the lens, he says.

The antenna concept is an extension of the team’s previous work, in which they developed a film made of graphene and silver nanowires that served as transparent, stretchable electrodes. The team reported that in April 2017, but at the time, they had not yet figured out a way to embed the antenna, sensors, or LED display into the lens.

Park’s team is joined by many others in the field drawn to the allure of smart contact lenses. Another group out of South Korea, for example, in 2016 reported the development of contact lenses that are powered and controlled by eyeglasses. The lenses can monitor glucose and dispense drugs. And Sensimed in Lausanne, Switzerland, has commercialized a pressure-sensing contact lens for tracking and diagnosing glaucoma.

Park says he and his team would like to apply the smart contact lens design to other medical applications, such as drug delivery. For the glucose monitoring application, he says he hopes for commercialization in the next five years.

source : www.spectrum.ieee.org