In pharmaceutical research, small tissue spheres are used as mini-organ models for reproducible tests. TU Wien has found a way to develop a reliable standard for these tissue samples.

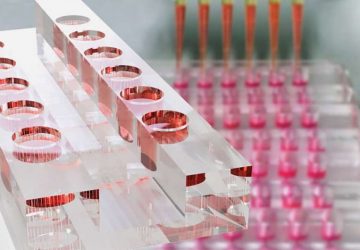

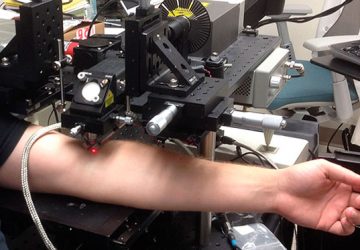

Before drugs are tested in clinical trials, they must be tested either by animal experiments or, more recently, artificially produced tissue samples. For this purpose, cells are cultivated, and tiny spheres with a diameter of less than one millimeter are made. However, the problem is that there have been no uniform standards for these tissue samples and no reliable method for producing them with uniform size and shape. Therefore, results from different laboratories are hardly comparable with each other, as the tissue size directly influences the behavior of cells and drugs.

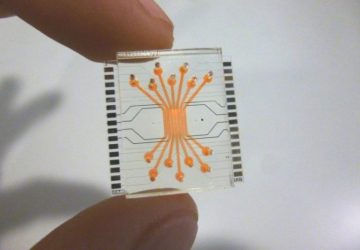

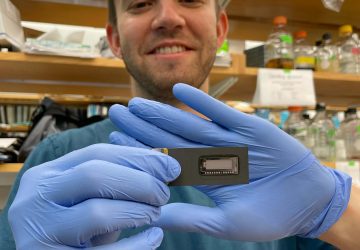

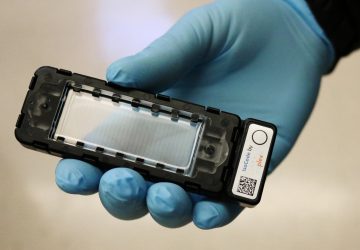

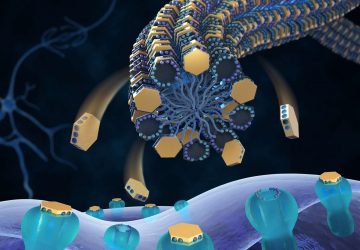

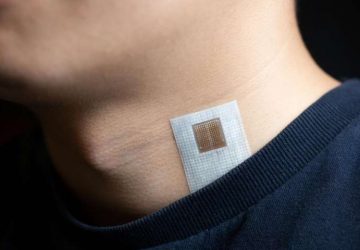

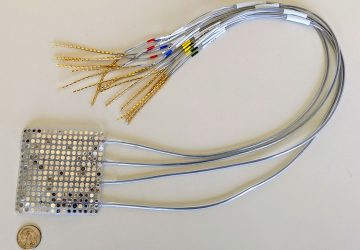

An invention by TU Wien can now solve this problem: A biochip has been developed that can be used to produce tissue beads in precisely the desired sizes and supply them with nutrients or even drugs through a thin channel. A patent application has already been filed for the new biochip technology.

Better preclinical studies

“In preclinical studies, drugs are tested on small tissue samples to understand them as well as possible before they can be administered to test subjects,” says Christoph Eilenberger, a doctoral student in Prof. Peter Ertl’s biochip research group at the Institute for Applied Synthesis Chemistry at TU Wien. Carrying out these studies with higher precision means taking the next step faster and more reliably.

Maximum scientific accuracy in these studies can save not only a lot of money but also a lot of time on the long road to producing a marketable drug. Well-defined tissue samples are also indispensable in other research areas—for example, when studying the development of tumor cells or when ensuring the safety of food or cosmetic products.

Standardizing size and shape

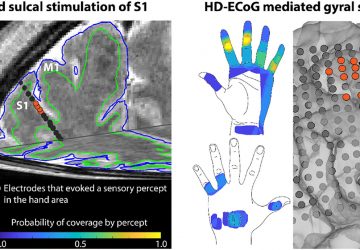

“The size of the samples is a crucial factor in all these studies,” says Mario Rothbauer, a postdoc at the Institute of Applied Synthesis Chemistry. “If the tissue consists of only a few cells, the environmental conditions are practically the same for all cells. For tissue spheres with a slightly larger diameter, differences begin to play a greater role, for example, when the concentration of certain chemicals is not the same everywhere.” Therefore, experiments are only comparable if you precisely standardize the size and shape of the tissue samples.

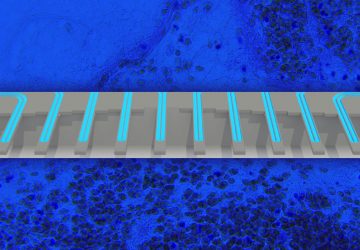

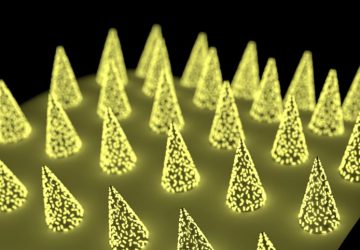

The biochip team at TU Wien investigated in numerous experiments how this can best be done: “We created cavities in our biochips with very different sizes and geometric shapes—cylinders, ellipses, spherical segments. They influence tissue growth in very different ways.” As it turned out, the radius of curvature is crucial; sharp edges are a disadvantage.

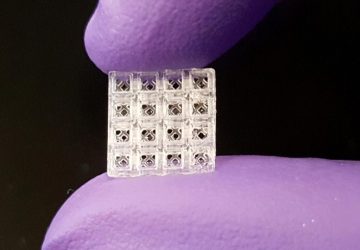

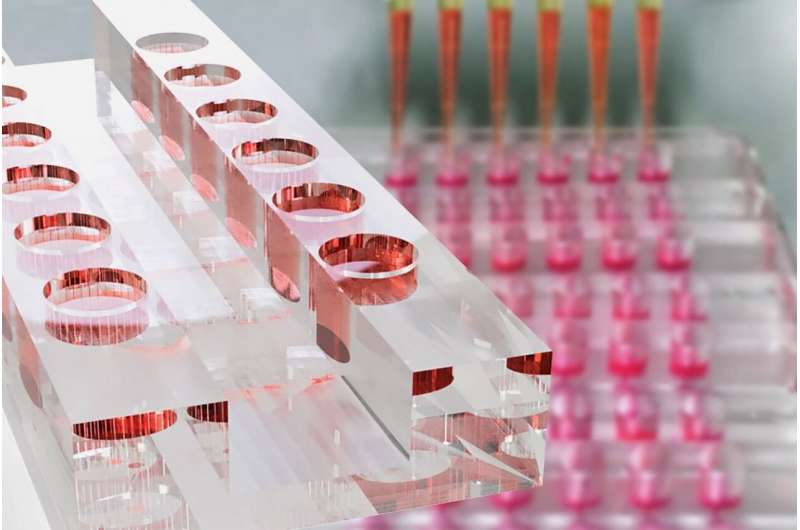

Success was finally achieved with hemispherical cell containers, with diameters between 0.1 mm and 1 mm. “Producing such shapes is not easy. We used microlenses, which are usually used for optical experiments,” says group leader Prof. Peter Ertl.

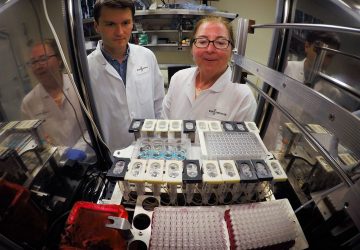

A whole series of these hemispheres is applied to the biochip and populated with cells. With a sophisticated system of fine tubes, it is possible, for example, to ensure that different cavities are supplied with varying concentrations of drug. This creates a precisely defined, standardized experimental environment on an area of just a few square centimeters.

Suitable for industry

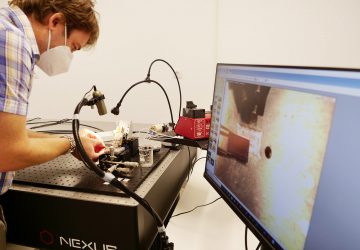

The new system was tested with different types of cells: “In one experiment we created an artificial blood-brain barrier. In another, we tested the effectiveness of a cancer drug,” says Christoph Eilenberger. “This allowed us to show that our chip performs well in typical preclinical tests.” The biochip is currently being used at the renowned Harvard Medical School, where Eilenberger is spending time abroad to research developed resistance of tumor cells to breast cancer drugs. The chip helps to standardize and replicate the patient’s specific tumor milieu with greater efficiency to make targeted therapy responses and predictions about the risk of relapse.

The design of the new method was designed from the outset for industrial suitability: Experiments can be automated, chips can be combined and stacked to produce and test large numbers of spherical cell samples in a short time. “The system is ideally suited for use in pharmaceutical research,” Mario Rothbauer is convinced, “which is why we have already applied for a patent for our idea, and we are already in talks with various companies from the pharmaceutical industry who are very interested in our new technology.”