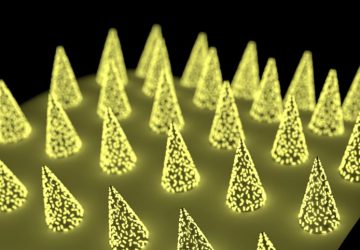

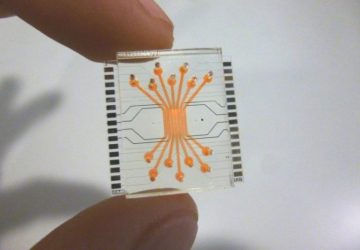

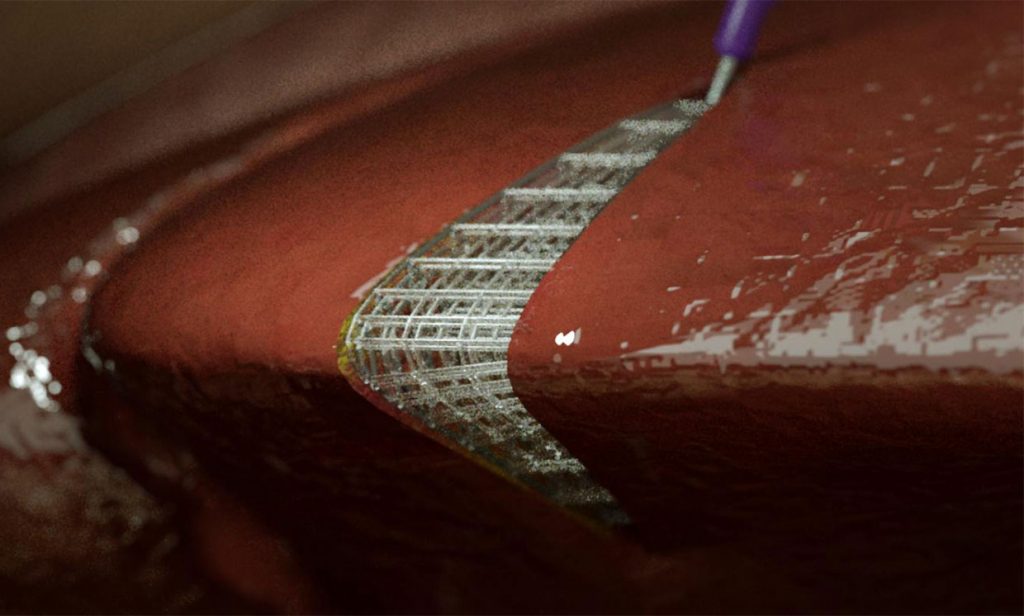

Bioprinting could happen via minimally invasive surgery

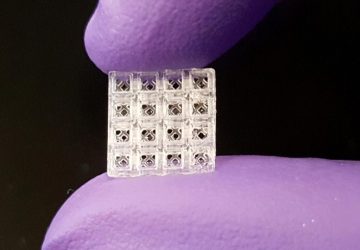

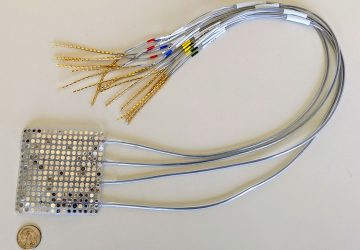

A lattice structure implanted directly into soft living tissue.

Right now, almost 70,000 people in the United States

alone are on active waiting lists for organ donations. The dream of

bio-printing is that one day, instead of waiting for a donor, a patient

could receive, say, a kidney assembled on demand from living cells

using 3-D printing techniques. But one problem with this dream is that

bio-printing an organ outside the body necessarily requires surgery to

implant it. This may mean large incisions, which in turn adds the

risk of infection and increased recovery time for patients. Doctors

would also have to postpone surgery until the necessary implant was

bio-printed, vital time patients might not have.

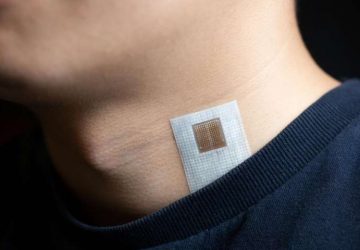

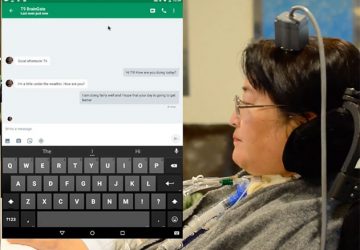

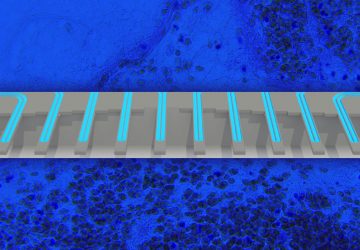

A way around this problem could be provided by new bio-ink, composed of living cells suspended in a

gel, that is safe for use inside people and could help enable 3-D

printing in the body. Doctors could produce living parts inside patients

through small incisions using minimally invasive surgical techniques.

Such an option might prove safer and faster than major surgery.

One challenge with bio-printing inside the body is that current bio-inks often require ultraviolet light in order to solidify, but ultraviolet rays can damage internal organs. Another problem is how to attach printed tissues effectively to soft live organs and tissues.

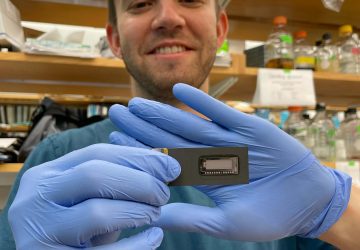

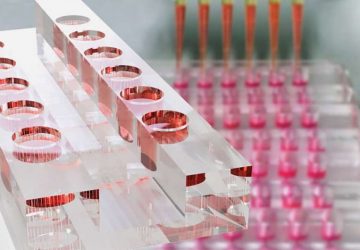

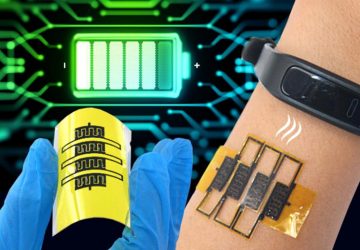

According to a new study published in the journal Biofabrication, researchers developed a bio-ink they could solidify using visible light. Moreover, the ink was printable at the kinds of temperatures found within the body—previous bio-inks were too liquid at body temperature to hold their shape when printed, says study senior author David Hoelzle, a mechanical engineer at Ohio State University.

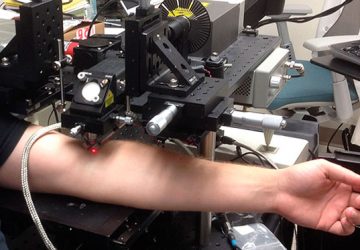

The scientists used a 3-D printing nozzle affixed onto robotic machinery. This strategy dispensed bio-ink much like an icing tube squeezes out frosting, only in a controlled, programmable manner. The researchers experimented with bio-printing onto soft materials, such as raw chicken breast strips and a gel similar to agar jelly. They first pierced the surfaces of these materials with the nozzle and extruded a little “interlock” knob into the punctured space. Next, they slowly withdrew the nozzle from the materials, trailing behind a filament of material they could keep on printing with.

The knobs left beneath the surface anchored the printed structure to the body, acting a bit like surgical staples, “but with a different type of material and with more flexibility with the shape of material,” Hoelzle says.

The scientists made their bio-printed structures porous to help immerse the cells in fluids carrying nutrients, oxygen and other molecules. Up to 77 percent of mouse cells in the bio-ink remained viable in the structures after 21 days, and the researchers found their strategy of using interlocks resulted in an up to four-fold boost in adhesion strength.

Hoelzle notes they can definitely optimize the interlocks to boost adhesion. “Just like different stitch patterns for textiles have different strengths, there are bound to be different interlocking patterns that improve upon these results,” he says.

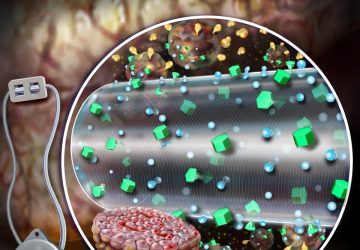

The researchers caution they do not aim to bio-print an entire heart or kidney in the body in a minimally invasive manner. “Even more traditional methods of delivery of tissue-engineering materials are years away from this accomplishment,” he says. Instead, “consider the ability to augment a standard surgery by delivering a biomaterial with a tethered growth factor to jumpstart healing, or a tethered drug to prevent infection.”

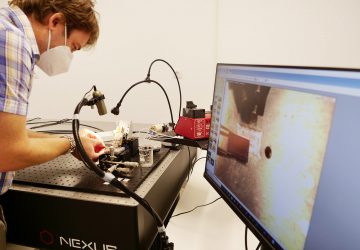

The scientists foresee bio-printing inside the body using robotic surgery instruments. “In a typical robotic surgery operation, the surgeon is operating four arms, two of them simultaneously,” Hoelzle says. “Each of the arms has an interchangeable tool, so the surgeon can swap out tools depending on what he or she needs at the moment. We envision a biomaterial-bioink printing tool as another tool in the surgeon’s toolset.”

Hoelzle and his colleagues are currently working on the first generation of an interchangeable bio-printing attachment for robotic surgery they aim to report before the end of this year, “although research restrictions from COVID are slowing us down,” he says.

source: www.spectrum.ieee.org